Toggle Nav

Nation Wide Supplier of Cylinder Heads

FREE SHIPPING TO CONTIGUOUS U.S.!!!

ASK OUR EXPERTS

1(818) 886-8041

1(818) 886-8041

Search

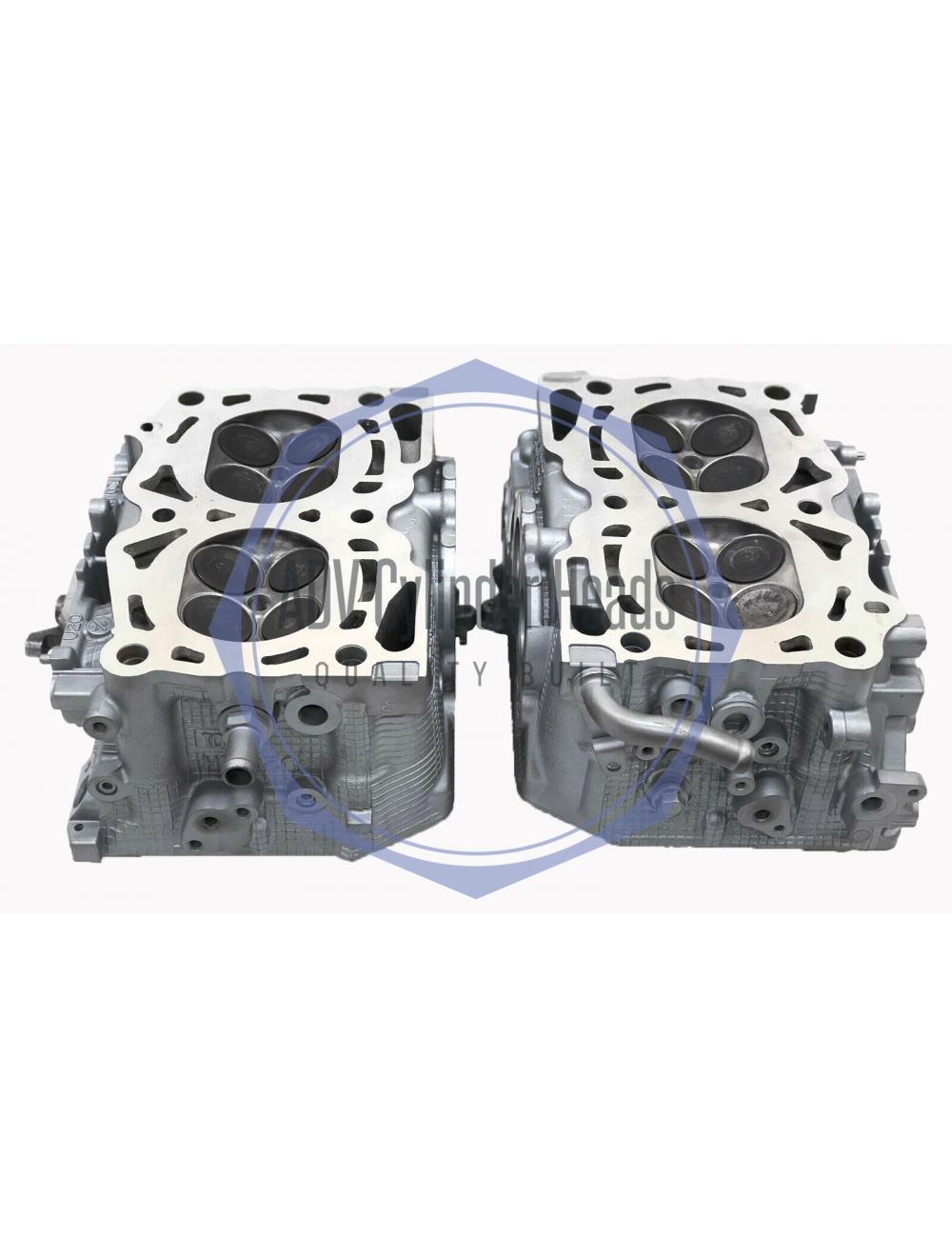

Subaru 2.0 DOHC F-4 TURBO Cast# U20 WRX STI EJ205 Cylinder Head Pair 2006-2018

Remanufacturing Process Includes:

- Complete disassembly and thorough cleaning via hot tank & pressure tested to confirm casting integrity

- New valve seats installed as necessary

- New valve stem seals installed on all our heads & all valve guides are replaced with new ones as necessary.

- Valve job Performed with all required angles & vacuum tested seals to ensure perfect compression.

- PCD milled to ensure a super smooth finish. (PCD stands for Polycrystalline Diamond, and is best for aluminum heads).

- All necessary parts are cleaned and inspected before final assembly to meet AERA specifications.

$1,539.99

Availability:

In stock

SKU

Subaru 2.0 DOHC #U20 Pair